F100-PW-229 Compressor Blade Repair with Cubic Boron Nitride (CBN) Coating

The high-performance F100-229 turbine engine, manufactured by Pratt & Whitney, powers various military aircraft. Its reputation for reliability, durability, and high operational performance is widely recognized in the aviation industry. However, regular inspections, maintenance, and repairs are critical to ensure optimal performance and safety, especially when operating in harsh conditions. One of the most common maintenance issues is blade coating caused by friction between the tip and the plasma coating or honeycomb of the shroud, which may be repaired through a turnkey solution offered by TAT Israel.

TAT Israel (former Turbochrome Ltd) has developed a technical blade maintenance and repair process that includes replacing the CBN coating at the tip of the blade. The Cubic Boron Nitride coating on compressor blade tips offers improved resistance to chipping, resulting in superior performance through improved tip sealing and increased airflow performance. This repair exceeds standard maintenance procedures, and TAT Israel strictly adheres to the manufacturer’s guidelines in its blade reconditioning process to maintain the original safety specifications.

Recently TAT Israel received the USAF approval for the replacement of Cubic Boron Nitrite (CBN) Coating on the F100-PW-229 Compressor Blade Tips, making it a USAF-approved source for the following alternative PWA 290 CBN Plating process.

Ref: AIR FORCE TO 2-1-111 NAVY (NAVAIR ) 02-01-517

Read further and discover how TAT Israel is transforming blade longevity with special coatings like Cubic Boron Nitride. In this article, we will explore:

- CBN coating tip repair of compressor blades

- Cubic Boron Nitride (CBN) coating efficiency

- Certification and inspection

- Cubic Boron Nitrite coating cost-effectiveness

- Repair Validation

The benefits of CBN coating on F100-229 Turbine Engine Compressor Blades

1. CBN coating tip repair of compressor blades

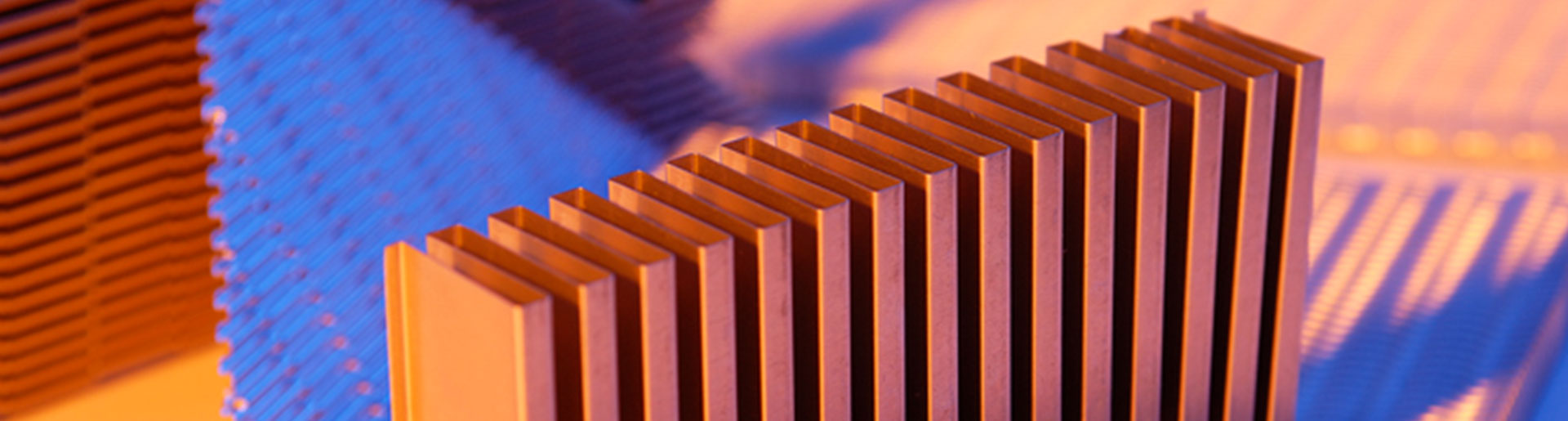

The blade tips undergo rubbing during engine operation due to the friction between the tip and the plasma coating or honeycomb of the shroud, located near the tip. A coating with good adhesion to the base metal will groove the seal and will enhance the airflow performance (refer to Fig 1 and 2.)

To prevent deterioration of the blade edge and improve the cutting performance of the plasma/honeycomb seal, the blade tips are inspected and then re-coated with Nickel layers and Cubic Boron Nitride (CBN) particles. CBN has a crystal structure similar to diamond and is approximately 70% as hard as diamonds, making it substantially harder than other conventional abrasives.

In response to market demands, TAT Israel has developed a process to replace the worn coatings on blade tips with New Nickel layers and Cubic Boron Nitride (CBN) coating. This technical solution comprises the performance and extends the lifespan of the jet engine.

2. Cubic Boron Nitride (CBN) coating efficiency

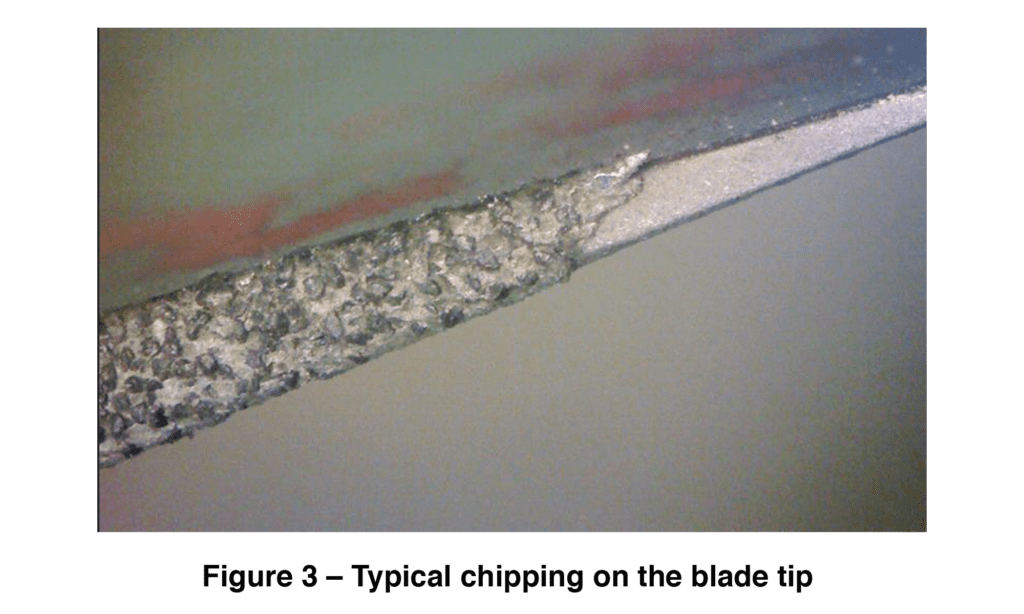

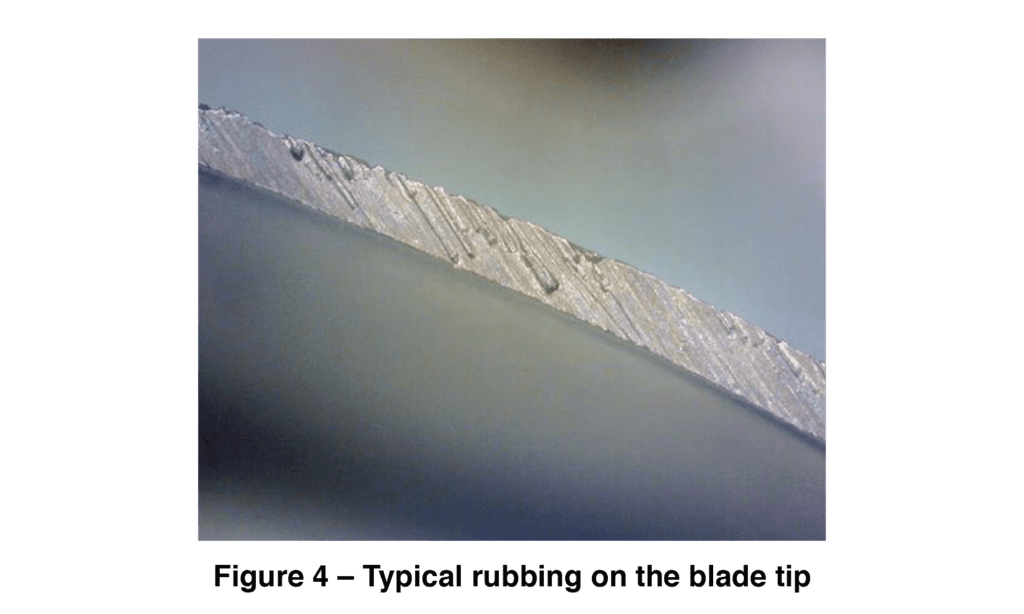

The effectiveness of TAT Israel’s coating can be measured by the number of blades that are rejected after service due to chipping, rubbing, and CBN coverage on the blade’s tip (refer to the typical chipping shown in Figure 3 and the typical rubbing coating shown in Figure 4).

The effectiveness of the CBN-coated tip displays the rejection rate of blades due to the chipping of the coating, rubbing, and lack of CBN particles. The end results indicate that the rejection rate of blades is comparable to that of reference blades and in some cases, even lower.

This improvement in adhesion properties results in cost savings as it eliminates the need to re–apply the tip coating during the next overhaul (O/H). By incorporating the CBN-coated tip, the capabilities of the engine can be significantly enhanced.

3. Certification and inspection

With a history dating back to 1969, TAT Israel has established itself as a trusted repair station for military and commercial jet machine engine turbines, compressors, and after-burner components. The company has received recognition from major aviation regulators, such as the FAA, EASA, and CAAC, and is approved by AS9100 and NADCAP for its rigorous evaluation process.

TAT Israel complies with aviation industry standards to ensure that its repair development processes maintain the original safety specifications of the blades. TAT Israel pays particular attention to complying with the manufacturer’s technical data in its components repair process to maintain its original safety specifications. Therefore, the risk of blade failure is low, with the worst-case scenario being a slight loss of the tip coating in isolated cases, which would not result in blade or engine failure.

4. Cubic Boron Nitrite coating cost-effectiveness

Low Scrap Rate of Blades with CBN Coating Chipping: TAT Israel offers a highly efficient CBN coating replacement process for Nickel and Titanium blades that ensures an acceptable low scrap rate within tight tolerances, reducing the cost of blade restoration.

Early Loss of CBN Coating: To prevent premature loss of the CBN coating and excessive rubbing of blade tips, it is essential to specify the right CBN coating replacement method. TAT Israel’s precision process helps reduce the risk of early loss and improves engine performance.

Efficient CBN Coating Replacement: TAT Israel’s CBN coating replacement method is more efficient than usual methods available on the market for Nickel and Titanium blades.

Competitive Pricing and Turn-Around Time: Thanks to the efficiency and precision of the process, TAT Israel offers highly competitive pricing and a short turnaround time for blade repair.

5. Repair Validation

In order to prove the repair quality and to receive customer acceptance, the blades repaired by TAT Israel (Turbochrome) have successfully passed an AMT test, followed by a full repair of compressor engine set Stages 4-13.

The blades repaired by TAT Israel were installed in a flying engine together with the original blades (OEM) as a performance reference and operated for 92 cycles (1st engine) and 246 cycles (2nd engine).

The total amount of blades evaluated (742ea – engine set) proved that TAT Israel repaired blades are of an equal quality as the reference blades, and in many cases even better than the original blades.

TAT Israel successfully passed the flight test phase and started to repair F100-PW-229 Compressor Blades Stages 4 – 13 in serial production

Summary

Don’t miss out on the opportunity to experience the quality of TAT Israel’s repairs for yourself and learn more about our technologies. If you’re ready to upgrade your engine performance, let’s discuss your needs and explore how our CBN coating can exceed your expectations.

Contact Yossi Ben David directly and discuss your specific needs, so we can provide you with personalized solutions that meet your requirements.

MORE NEWS

-

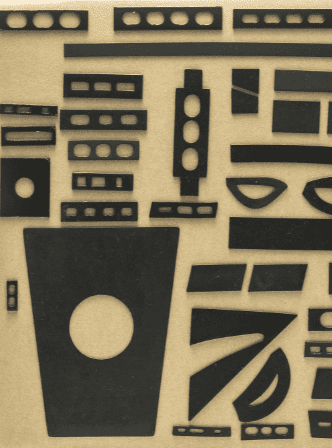

February 09 2023 Blog

Maskant Material Solutions for Aerospace and Industrial Engines

-

December 01 2022 Blog

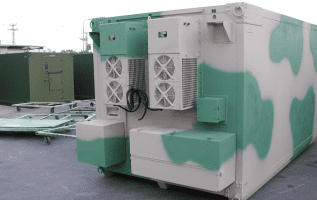

December 01 2022 BlogBACK TO BASICS: WHY COOLING SOLUTIONS SHOULD BE...

Controlling the temperature and humidity in your base camp, tents or

-

June 01 2022 Blog

June 01 2022 BlogWhy should all mission-critical military Environmental Control Units...

The art of maintenance is as old as people have figured out that they