Maskant Material Solutions for Aerospace and Industrial Engines

How to reduce the overall cost associated with your current aerospace industry maskant material solution?

Replace Traditional Time-Consuming Tapes, Powders and Slurries Maskant Materials

Masking is the process of applying a material to a surface to protect it from the environment or to act as a barrier during a manufacturing process.

Masking products can be placed onto the surface to be masked, and the maskants cure quickly to provide a durable coating that can be easily removed when no longer needed. This method of masking is faster and more efficient than traditional methods and can be used in a wide range of applications.

However, holding different products in inventory is not an economical solution. Read further to learn how we can help.

Aerospace tapes for a wide range of surface protection applications

Tapes are used for many different purposes in the aerospace industry. They usually have to meet very high standards and technical specification on order to withstand extremely high temperature and harsh chemicals. The aerospace industry is a special challenge for companies that make tapes because aircraft applications are very demanding. Tapes must demonstrate exceptional performance in order to satisfy the requirements of the aerospace industry.

TAT’s line of aerospace tapes is designed to meet the specific requirements of aircraft applications and provide outstanding performance.

What makes TAT Israel’s Maskant Materials products better?

Masking Tapes:

TAT’s T-Blocks Masking System is a multi-layer masking solution composed from a mixture of Nickel and Aluminum Oxide powders, mixed with an organic binder. Our proprietary manufacturing process creates a one whole stand-alone and ready to use product that includes two layers:

- Protective layer that acts as a “target” to the diffusion coating

- Separation layer that prevents the protective layer from sintering to the base metal

Both products serve the same purpose of high-temperature coating masking. However, the putty is extremely flexible which allows protection at sharp edges and corners, while the tape is less flexible and used mainly on straight surfaces.

T-Block masking eliminates the need for ordinary masking methods associated with powders and slurries and provides a more accurate method with no coating leakage or masking leakage.

We provide two main tapes:

- T-1525 T-Block Tape which is mainly used on straight surfaces and enjoys a 3-year shelf-life.

- T-1567 T-Block Putty which is an extremely flexible tape, allowing protection at sharp edges and corners with 3-year shelf life.

Slurries:

A special masking paste developed for Root Area Masking of turbine blades. It seals the masking box to prevent coating vapors from penetrating to the root area. In combination with Root Bottom Face pre-form our slurry will allow simultaneous internal and external coatings.

Do you want to hold only one item in inventory and reduce your overall MRO costs?

By choosing TAT’s Masking System you get the simplest and easiest way to prevent coating formation with the most reliable protection of components and exceptional performance.

More so, our solution will reduce your overall cost by:

- Reducing you labor cost to mask

- Reducing your inventory

- Reducing your material waste

Summary:

TATs T-Blocks Masking System is a proven technology, trusted by various international clients that utilize our products for high-temperature diffusion coatings on turbine blades and vanes, for new or overhauled aero/jet engines and industrial engines.

Need help? Contact us to learn more about our masking solution and start saving now!

Our engineers and sales team will ensure you will receive the most appropriate and high-performance solution to your specific requirements. Our custom products will provide reliable surface protection not available from traditional masking materials.

We deliver fast and up to 30 days.

Contact Yossi Ben David directly to discuss your exact needs.

MORE NEWS

-

March 20 2023 Blog

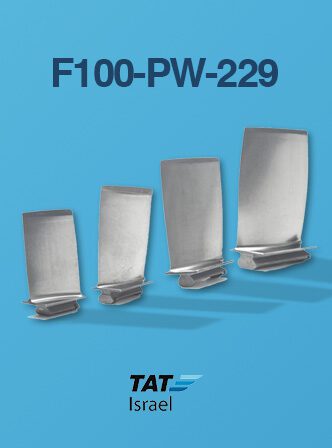

F100-PW-229 Compressor Blade Repair with Cubic Boron Nitride (CBN) Coating

-

December 01 2022 Blog

December 01 2022 BlogBACK TO BASICS: WHY COOLING SOLUTIONS SHOULD BE...

Controlling the temperature and humidity in your base camp, tents or

-

June 01 2022 Blog

June 01 2022 BlogWhy should all mission-critical military Environmental Control Units...

The art of maintenance is as old as people have figured out that they